When would you choose a Variable Frequency Drive?

A Variable Frequency Drive (VFD) is a great choice if you have a single motor that either needs 3 phase power or to be speed controlled. It is a cost effective choice for phase conversion if the motor will be controlled directly from the VFD rather than from buttons or a computer on your machine.

Examples where a VFD is great option include a stand-alone pump or compressor, a saw that has simple on and off controlls, or a fan. It is not suitable to power both a motor and its on-board computer system. It is also not ideal when a machine has controls beyond on/off as these controlls would need to be rewired to go through the VFD.

What does a VFD do?

A VFD is primarilly used to control the speed of a motor. This is great when you need to adjust the speed of your operation (eg. speed up a drill press or slow down a conveyor belt), or when you want to start or stop slowly.

Starting and stopping a motor gradually is hugely beneficial. It is easier on your equipment extending the life of your motor. It also reduces the total power requirements because a slowly starting motor draws less amperage.

What a VFD does NOT do?

Transform Voltages

A VFD can do phase conversion and speed control but it cannot change voltages. If you provide a VFD with 240 volts then it will output 240 volts. If your machine needs a different voltage (eg. 400v, 460v, 480v, 575v, 600v), then you will need a transformer. We carry a wide variety of transformers and probably have something to suite your needs.

Power a Machine's Control Board

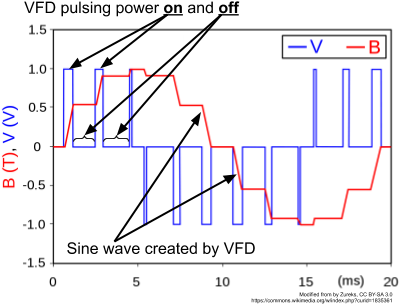

VFDs are designed to be connected directly to a single motor. They are not designed to power the control board of a machine. This is because VFDs do not create a constant electrical output. Instead, they pulse electrical signals out in direct proportion to what the attached motor needs. Motors can easily handle these pulses because they contribute to the magnetic field they produce, however, control systems usually don't like power that switches on and off.

If you need to power both a machine's motor and its controls then you will need a digital or rotary phase converter.

About Digital Learn More

About Rotary

Process Automation

A VFD can be programmed to help you automate your process. There are quite a lot of brains packed into these little boxes.

VFDs for Water Systems

You can use a VFD to target a specific pressure in your water system. You can specify that you want your water system to run at 60 PSI so if it drops below that then have the VFD kick in to pump in a bit more water. When a tap turns on, then the VFD will sense through an attached transducer that the pressure has dropped. It will then power up the pump until it reaches the desired pressure.

Sequence and Speed Control for Augers

You may have a complicated setup with many augers and conveyor belts that move grain. When you turn on your system, you will want the furthest away auger to start first. Only after it starts, do you want the one that feeds it to start, and so on.

When you hit stop, you want the first auger to run for a period of time to empty before stopping. Then you want the second auger to run for a period of time before stopping, and so on.

VFDs are smart and can be programmed to work together. You can automate your process based on sensors and how you interconnect the system.

VFD Controlling a Driveway Gate

Here's a driveway gate operator we built that shows how sensors can be connected to a VFD to control a complicated operation. This gate gradually accellorates, crosses the driveway, slows down and then bumps into the end point position. It responds to sensor inputs that allow it to determine if it is safe to close.

VFD Lab

When we build new VFD programs or we are troubleshooting a scenario that one of our customers may be experiencing, we have a VFD lab. This allows us to connect sensors and switches to the VFD to observe its behaviour.

Have Questions?

Talk to one of our Journeymen Electricians

Contact Us